Researchers at MIT have unveiled a novel method to reduce both the cost and environmental impact of concrete construction by substituting traditional wooden formwork with minimally processed, earth-derived mud. Traditionally, wooden forms are required to mold concrete, a step that is both expensive and time-consuming. The innovation spearheaded by Sandy Curth, a PhD candidate in MIT´s Department of Architecture, leverages waste soil or onsite earth as the base material, transforming it into precise and customizable formwork through additive manufacturing processes.

Known as the EarthWorks method, this approach enhances local soil with additives like straw and coats it with a waxlike substance, allowing the mixture to be 3D-printed into any required shape. The resulting formwork can be infinitely recycled after use, as it is fundamentally just dirt, according to Curth. This flexibility enables the fabrication of complex, shape-optimized components that require only the minimum necessary concrete, improving resource efficiency and contributing to reduced carbon emissions in the construction sector.

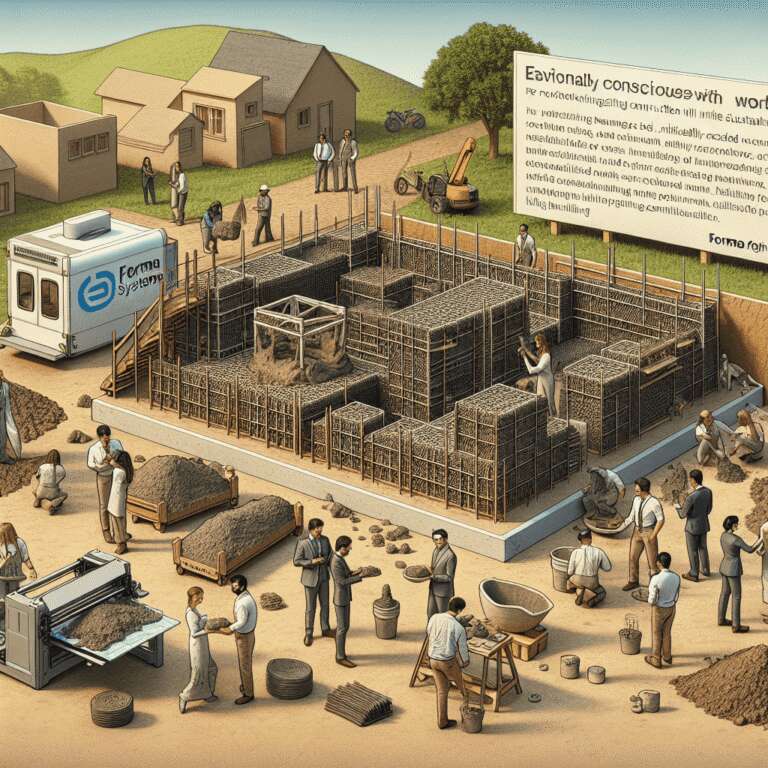

The process is as fast and energy-efficient as producing traditional straight-edged concrete forms, but offers far greater versatility in design. The work has been documented in a paper coauthored with MIT professors Lawrence Sass and Caitlin Mueller, among others, and Curth has founded the company Forma Systems to commercialize the technology and drive its adoption in the building industry. The EarthWorks method stands out for its sustainability, cost-effectiveness, and the potential to advance environmentally responsible architecture by harnessing locally available, recyclable materials.