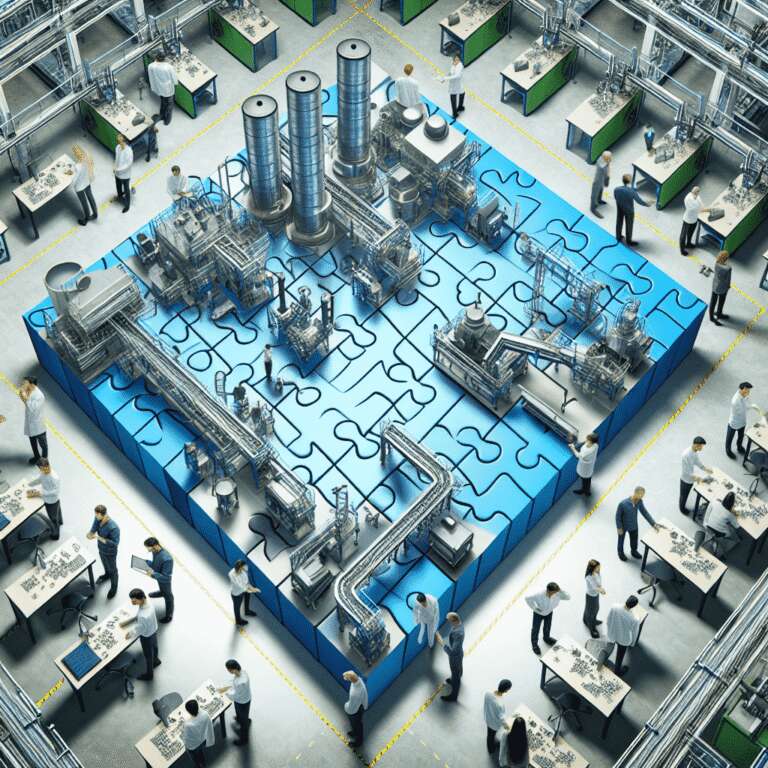

NVIDIA, in collaboration with major players in Taiwan´s manufacturing sector such as Delta Electronics, Foxconn, TSMC, and Wistron, is demonstrating the transformative potential of digital twins at COMPUTEX in Taipei. Using Universal Scene Description (OpenUSD) and NVIDIA Omniverse’s advanced software libraries, these companies are building comprehensive and physically accurate digital models of their factories. This digital twin approach enables unprecedented operational efficiency and supports the rapid deployment, testing, and validation of autonomous robots and complex robotic fleets.

Manufacturers are increasingly integrating real-time data and advanced analytics into their factory digital twins. Foxconn’s Fii Digital Twin platform allows engineers to simulate and optimize the flow of materials, equipment, and personnel, enabling fast adaptation of factory designs for new deployments. The company uses Omniverse blueprints, NVIDIA cuOpt, and Isaac Sim to dynamically plan and commission new factories, while engineering teams leverage Cadence’s digital twin software to accelerate thermal simulations and reduce energy risks and costs. TSMC is enhancing its facility planning by collaborating with startups to convert 2D designs into interactive 3D digital twins, enabling better equipment placement and system optimization, while utilizing Artificial Intelligence models for defect detection and to streamline the chip design process. Wistron employs its WiDT platform to connect generative Artificial Intelligence tools with live production data to optimize plant layouts, improve machine performance, and accelerate workforce training through curated video content powered by NVIDIA’s VSS blueprint.

This digital transformation extends beyond traditional manufacturing. Companies like Pegatron are launching platforms such as PEGAVERSE and PEGAAi for predictive maintenance and remote monitoring, helping reduce labor costs and defect rates significantly. Kenmec, MetAI, and GIGABYTE use Omniverse for logistics and operational monitoring, and Quanta Cloud Technology facilitates real-time cross-functional collaboration by connecting digital twins to the engineering and supply chain ecosystems. In the context of robotics, Delta Electronics employs Isaac Sim to virtually train all robot types, including manipulators and AMRs, and plans to offer cyber-physical training platforms for customers. Techman Robot and Foxlink are refining robot intelligence and reducing programming time by simulating tasks in Omniverse, achieving major productivity improvements for industrial and logistics robots. In healthcare, Adata and Advantech have used digital twins and autonomous mobile robots to make hospital disinfection 3x faster, while Ubitus trains humanoid robots to address labor shortages in medical facilities. These applications highlight how NVIDIA Omniverse is placing digital twins at the heart of Taiwan’s new industrial era, fostering advances in manufacturing, robotics, automation, and workforce development.