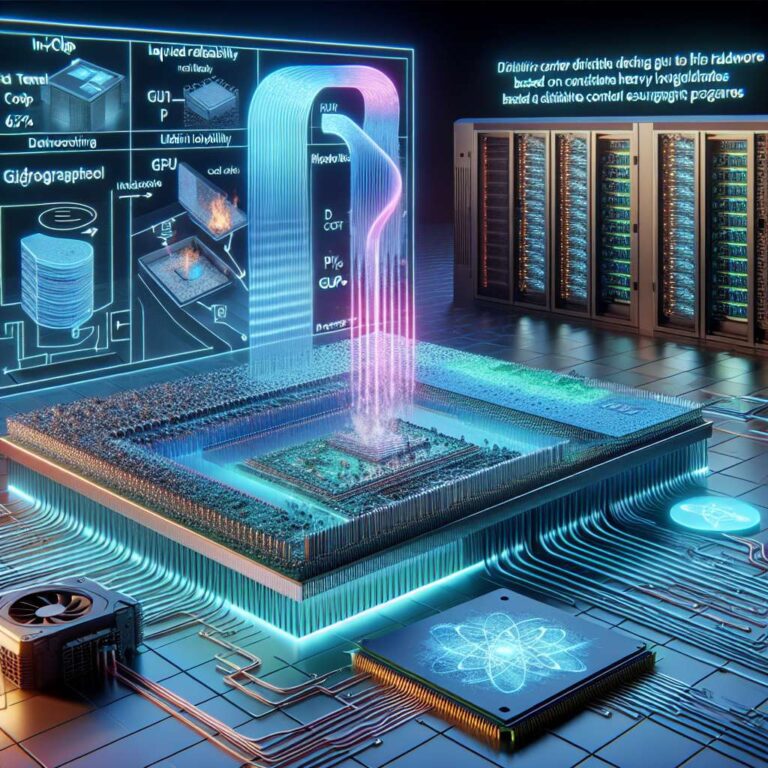

Microsoft has introduced a new in-chip microfluidics cooling system designed to improve the efficiency and sustainability of artificial intelligence hardware. The approach routes liquid coolant directly across a chip’s silicon surface, which the company says reduces thermal resistance compared to traditional cold plates that sit on top of processors. According to early testing cited by Interesting Engineering, the system cut a graphics processing unit’s temperature rise by up to 65 percent and cooled as much as three times more efficiently than advanced cold-plate alternatives.

The method etches ultrathin grooves into the chip so coolant can flow precisely where it is needed. Microsoft pairs the hardware with artificial intelligence that detects hot spots in real time and dynamically directs cooling to those areas. The technology has been successfully tested on a server running simulated Microsoft Teams meetings, demonstrating real-world applicability in a data center-style environment.

Microsoft leaders frame microfluidics as a foundation for the next generation of power-dense designs, enabling better performance in smaller footprints. Corporate vice president Judy Prist said the team first needed to prove the technology and validate reliability, underscoring the company’s emphasis on long-term durability. Senior technical program manager Sashi Majety contrasted the approach with legacy cold plates, arguing that sticking with traditional methods limits progress.

Beyond performance, the company positions the innovation as an energy and cost saver for large-scale infrastructure that supports artificial intelligence workloads. Artificial intelligence systems are highly energy intensive, and reducing the power required for cooling could lower operating costs and lessen carbon pollution from data centers. The efficiency gains could also enable denser server deployments, potentially reducing the need for new data center construction and the associated environmental impact.

Technical fellow Jim Kleewein highlighted a broad set of benefits from microfluidics, noting improvements in cost, reliability, speed, and consistency, alongside sustainability. If the results scale in production environments, the technology could become a building block for more efficient artificial intelligence servers and infrastructure, aligning performance ambitions with stricter energy and environmental constraints.