Elon Musk told followers that Tesla has maintained an advanced Artificial Intelligence chip and board engineering team for years and that the group has already designed and deployed several million Artificial Intelligence chips across Tesla cars and data centers. He framed those chips as the key to Tesla’s leadership in “real‑world Artificial Intelligence” and said the company now operates on an annual product cadence, releasing new platforms roughly every 12 months.

Musk said Tesla aims to manufacture chips at volumes higher than every other maker to support its ambitions. The article notes this is consistent with prior statements from Musk about a potential target of up to 200 billion Artificial Intelligence chips per year to support a larger fleet and new projects such as Optimus and Cybercab. The story also records skepticism about that scale, calling such demand far‑fetched and difficult to meet with current industry resources.

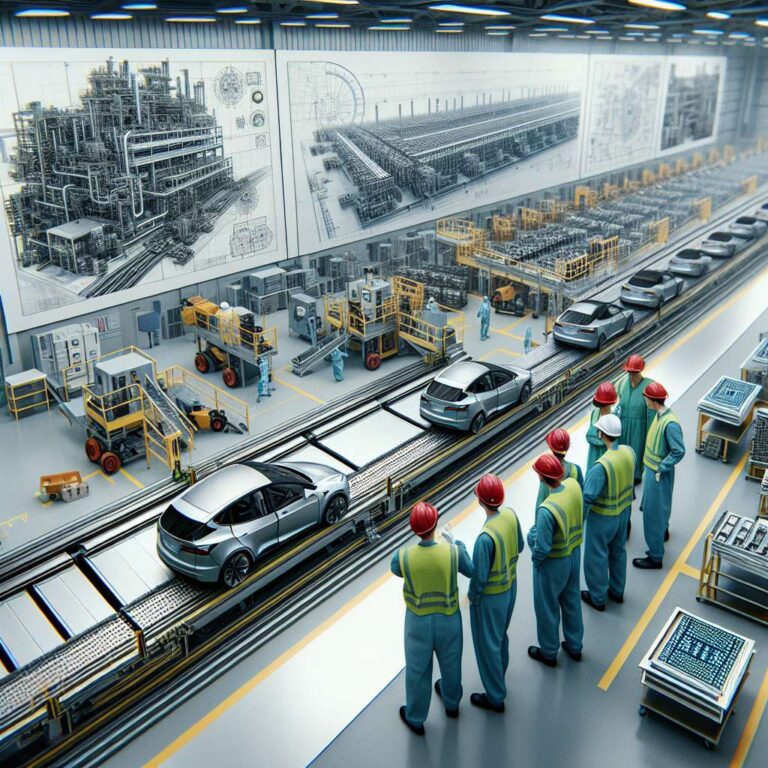

To address production constraints, Musk outlined more optimistic plans, including a so‑called “TeraFab” buildout and a diversified sourcing strategy. Tesla has been working with foundries such as TSMC and Samsung for AI5 and next‑generation AI6 chips and plans to add Intel Foundry to the mix. Even so, Musk has argued that existing chipmakers cannot meet the demand he expects, which is motivating moves toward building up a broader supply chain and in‑house capacity.

The article concludes that creating a chip supply chain at the scale Musk envisions is complex and outside Tesla’s traditional expertise. It points to previous efforts to assemble pieces of a semiconductor supply chain for space and other businesses and argues Tesla will likely need significant collaboration and new manufacturing capacity to attempt the volume Musk describes.