Artificial Intelligence chips are running hotter as new architectures drive higher performance, and conventional cooling is reaching its limits. Microsoft says it has successfully tested an in-chip microfluidic system that brings liquid coolant directly into the silicon, removing heat up to three times better than advanced cold plates depending on workload and configuration. Microchannels etched into the back of the chip allow coolant to flow precisely where heat is generated, and Microsoft used Artificial Intelligence to identify each chip’s thermal hotspots so the coolant can be routed more efficiently.

In lab-scale testing, the approach reduced the maximum temperature rise inside a GPU by 65 percent, though the exact benefit varies by chip type. The system has effectively cooled a server running core services for a simulated Microsoft Teams meeting, indicating readiness beyond benchtop experiments. Microsoft expects the technology to improve power usage effectiveness and reduce operational costs by enabling warmer coolant temperatures and better heat removal than traditional methods, which are constrained by multiple layers that sit between a chip and a cold plate.

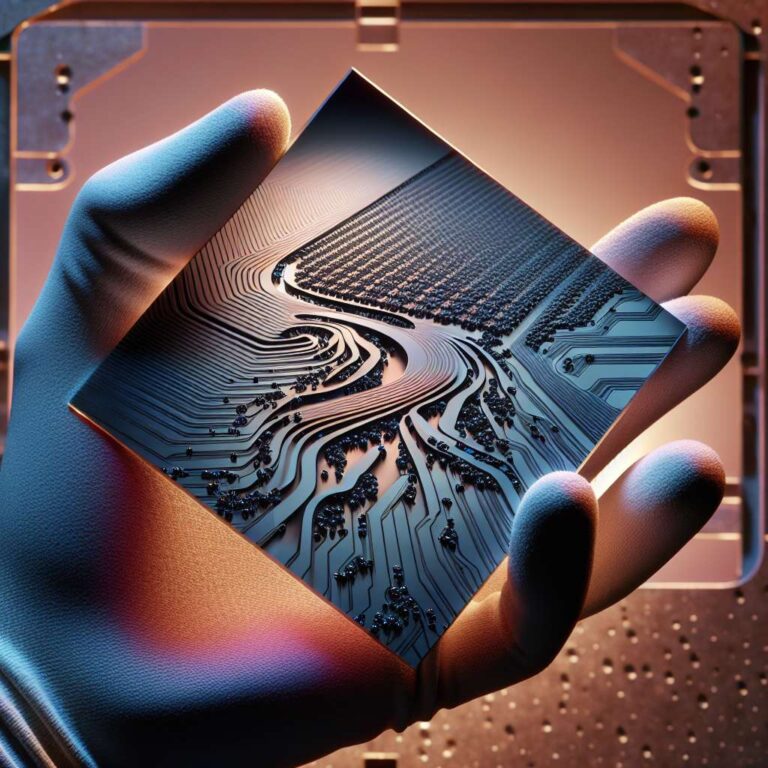

Building a practical microfluidic solution required system-level engineering across silicon, coolant, servers and datacenters. Microsoft collaborated with Swiss startup Corintis to use Artificial Intelligence for bio-inspired channel designs that cool hotspots more efficiently than straight channels. The channels are hair-width and must be deep enough to circulate coolant without clogging yet not so deep that they weaken the silicon. The team iterated on leak-proof packaging, coolant formulations, etching methods and a manufacturing flow to add etching steps, producing four design iterations in the past year.

The company positions microfluidics as a way to enable more power-dense hardware and to manage spiky workloads more economically. For services like Teams, where activity surges around meeting start times, the improved thermal headroom could support safe overclocking during peaks instead of overprovisioning servers that sit idle most of the time. Liquids conduct heat better than air, and by removing insulating layers and cooling the silicon directly, microfluidics can operate with less-chilled fluid, saving energy and improving opportunities for high-quality waste heat use.

Microsoft is investigating how to integrate microfluidic cooling into future generations of its first-party chips, including its Cobalt and Maia families, and plans to work with fabrication and silicon partners to bring the technology into production across its datacenters. Beyond immediate efficiency gains, the company sees microfluidics as a path to denser racks and new chip architectures such as 3D stacking, where fluid could flow between stacked dies. Microsoft also encourages industry-wide adoption, arguing that broader use will accelerate innovation and sustainability benefits for cloud infrastructure.