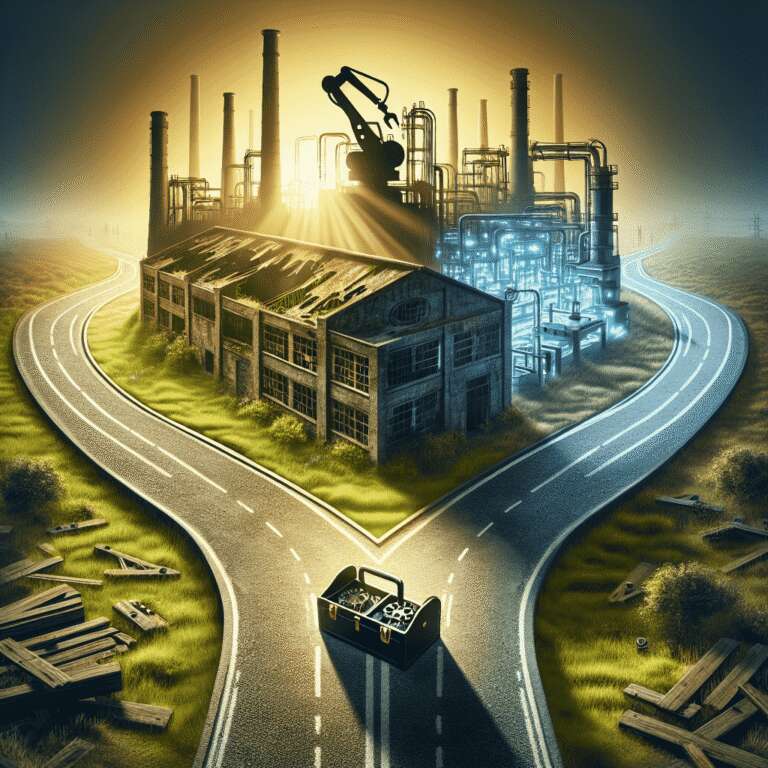

The manufacturing industry is currently facing significant challenges due to geopolitical instability affecting supply chains, rising costs, inflation, and a dwindling labor force with over 500,000 unfilled manufacturing positions in the U.S. alone. This is compounded by climate change and increasingly stringent environmental regulations, prompting companies to reconsider their operational strategies.

Advanced automation, through emerging technologies like industrial Artificial Intelligence, digital twins, IoT, and robotics, promises to deliver increased resilience, flexibility, and efficiency. These technologies have exhibited their potential in success stories: AI-driven maintenance can cut downtime by up to 50%, while digital twin simulations accelerate market time and reduce carbon emissions by an average of 15% according to business leaders.

However, widespread adoption of these technologies remains challenged by issues beyond technological capacity, including workforce skill gaps and financial investment risks, especially for small and medium-sized enterprises with older facilities. Governments have begun to promote industrial advancements by incentivizing high-tech manufacturing and localizing key production processes, aiming to mitigate dependence on global supply chains. These converging factors in technology and policy could facilitate a long-awaited shift toward advanced automation in the industry.