The covid-19 pandemic exposed fundamental vulnerabilities in global supply chains, with lockdowns causing extended factory closures and massive disruptions across international trade routes. This chaos led to widespread shortages, soaring costs, and unpredictable demand swings, rendering traditional forecasting and inventory management tools ineffective. As Matthias Winkenbach from the MIT Center for Transportation and Logistics points out, the pandemic was an unforeseen ´black swan event´ that disrupted long-standing practices like just-in-time inventory and highly interconnected, lean supply networks.

Other recent disruptions, such as the six-day blockage of the Suez Canal in 2021, have underscored the inherent fragility of global supply systems still further. The event, which stalled roughly 30% of worldwide container traffic, had an immediate and severe economic impact, emphasizing that catastrophic supply chain events have become an all-too-common reality. These incidents have prompted a reassessment of risk and resilience across the industry, driving home the need for more robust and flexible systems that can withstand shocks yet maintain operational continuity.

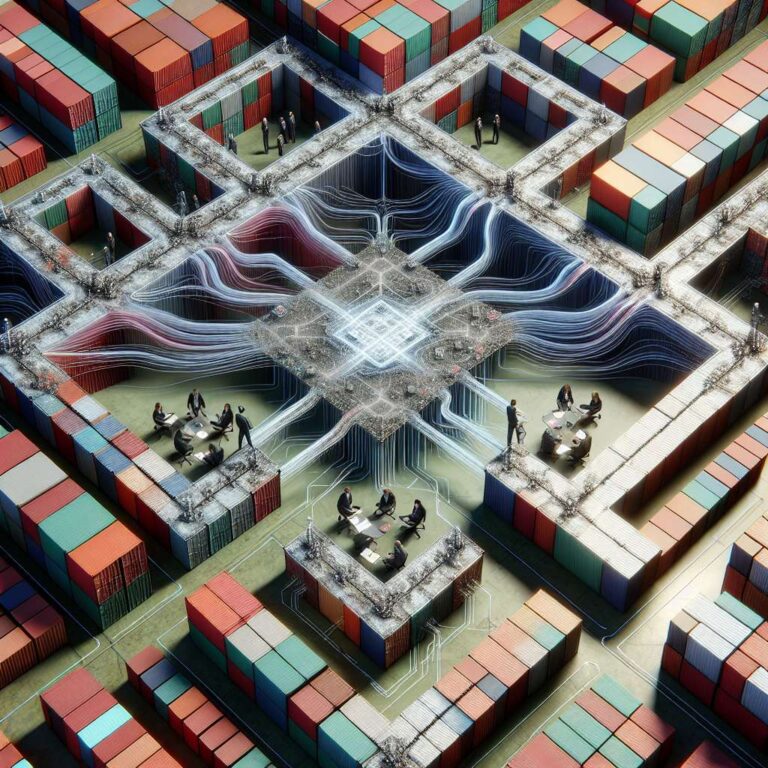

In the search for solutions, generative artificial intelligence has emerged as a transformative tool for shoring up supply chains against future threats. With 86% of CEOs now prioritizing resilience within their organizations’ supply strategies, businesses are turning to generative artificial intelligence to surface hidden risks and suggest creative solutions for rerouting and mitigation. Unlike legacy systems, generative artificial intelligence rapidly adapts to new data and scenarios, empowering companies to navigate uncertainty with greater agility. As organizations seek to future-proof their supply operations, generative artificial intelligence’s role in forecasting, planning, and risk management is set to become indispensable in global logistics.