A new 3D-printed design could make an integral part of cooling systems smaller and more efficient, according to recent research. This innovation targets heat exchangers, devices critical in managing temperature control across various sectors such as data centers and buildings. Traditional designs tend to favor simple constructions more easily manufactured using standard methods.

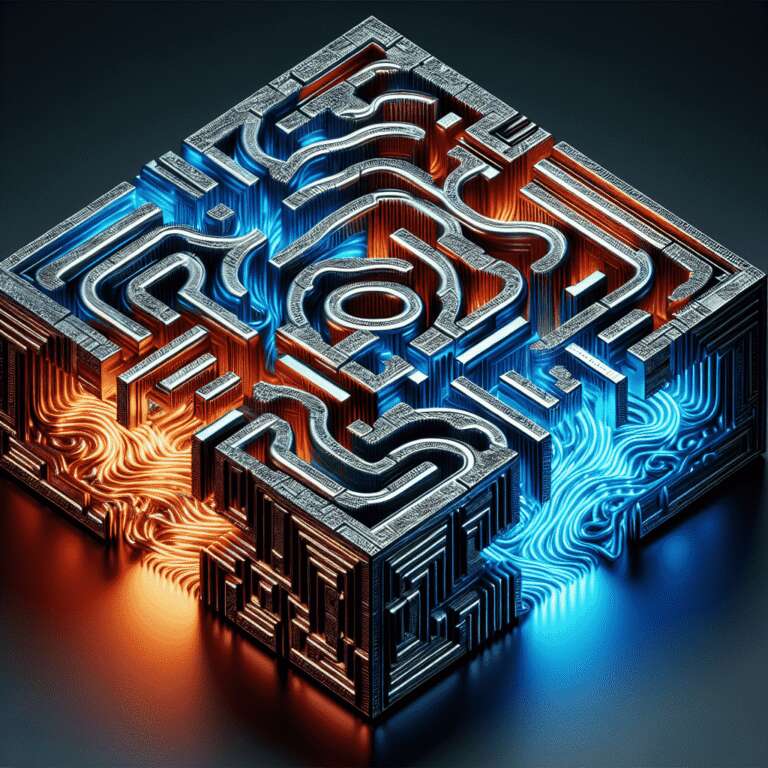

Researchers led by William King utilized 3D printing to create a heat exchanger with features that optimize heat transfer, including wavy walls and pyramid-shaped bumps. This would be impossible to achieve with conventional techniques. The inventive design focuses on enhancing the interaction between the device´s cold water side and the refrigerant, using thin walls and extended contact surfaces to maximize cooling.

The research team used simulations assisted by machine learning to refine their prototype out of 36,000 trials. The finalized exchanger includes fins and specifically curved passageways to improve efficiency. Although the production process, direct metal laser sintering, remains slow and costly, the tool´s superior power density suggests potential benefits for specialized industries like aerospace and high-end automotives. Nonetheless, adopting such advanced industrial applications widely might be years away due to current manufacturing constraints and standard efficiency requirements.